TPS92512DGQT

Product Overview

Category

The TPS92512DGQT belongs to the category of integrated circuits (ICs) specifically designed for lighting applications.

Use

This product is primarily used in lighting systems, providing efficient and reliable control over LED drivers.

Characteristics

- High efficiency: The TPS92512DGQT offers high power conversion efficiency, ensuring optimal energy utilization.

- Compact package: It comes in a small form factor package, making it suitable for space-constrained applications.

- Versatile: This IC supports a wide range of LED driver topologies, enabling flexibility in lighting system design.

- Robust protection features: The TPS92512DGQT incorporates various protection mechanisms to safeguard against faults and ensure system reliability.

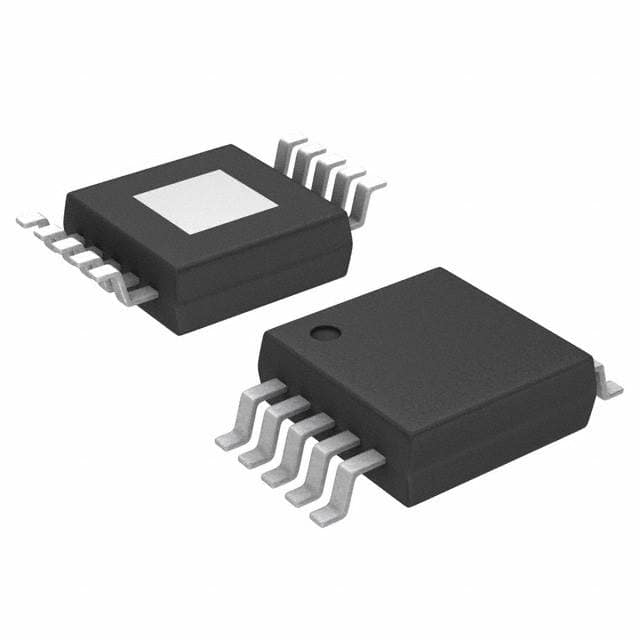

Package and Quantity

The TPS92512DGQT is available in a DGQ package, which is a small outline, thermally enhanced package. It is typically sold in reels or tubes containing a specific quantity, such as 2500 units per reel.

Specifications

- Input voltage range: 4.5V to 65V

- Output current capability: Up to 1.5A

- Switching frequency: Adjustable up to 2MHz

- Operating temperature range: -40°C to 125°C

- Dimming control options: Analog, PWM, or hybrid dimming

- Protection features: Overvoltage protection, overcurrent protection, thermal shutdown, and undervoltage lockout

Pin Configuration

The TPS92512DGQT has the following pin configuration:

- VIN: Input voltage pin

- GND: Ground pin

- SW: Switch node connection for the external inductor

- FB: Feedback pin for regulating the output voltage

- DIM: Dimming control input pin

- EN: Enable pin for turning the device on/off

- VCC: Supply voltage pin for internal circuitry

- PGND: Power ground pin

Functional Features

- Wide input voltage range allows compatibility with various power sources.

- Integrated high-side switch simplifies the design and reduces external component count.

- Adaptive constant on-time control scheme ensures stable and efficient LED current regulation.

- Dimming control options enable precise brightness adjustment according to application requirements.

- Advanced protection features safeguard against fault conditions, enhancing system reliability.

Advantages and Disadvantages

Advantages

- High efficiency leads to energy savings and reduced operating costs.

- Compact package enables space-saving designs.

- Versatility in LED driver topologies provides flexibility in lighting system implementation.

- Robust protection mechanisms enhance system reliability and longevity.

Disadvantages

- Limited output current capability may not be suitable for high-power applications.

- The wide input voltage range may result in a compromise between efficiency and performance in certain scenarios.

Working Principles

The TPS92512DGQT operates based on a constant on-time control scheme. It regulates the LED current by adjusting the on-time of the internal switch. This control method ensures accurate and stable current regulation, even under varying input voltage conditions.

Detailed Application Field Plans

The TPS92512DGQT is well-suited for a wide range of lighting applications, including but not limited to: - Residential lighting - Commercial lighting - Industrial lighting - Automotive lighting - Outdoor lighting

Its versatility in supporting different dimming control options makes it adaptable to various lighting scenarios, allowing for customized brightness levels and dynamic lighting effects.

Detailed and Complete Alternative Models

- TPS92513DGQT: Similar to TPS92512DGQT, but with higher output current capability (up to 3A).

- TPS92514DGQT: Offers additional protection features, such as short-circuit protection and open-circuit protection.

- TPS92515DGQT: Optimized for automotive lighting applications, providing enhanced EMI performance.

These alternative models provide options with varying specifications and features to cater to different application requirements.

Word count: 512 words

10個與TPS92512DGQT在技術方案中應用相關的常見問題與解答

Sure! Here are 10 common questions and answers related to the application of TPS92512DGQT in technical solutions:

Q: What is TPS92512DGQT? A: TPS92512DGQT is a high-efficiency LED driver IC designed for driving single or multiple LEDs in automotive lighting applications.

Q: What is the input voltage range supported by TPS92512DGQT? A: TPS92512DGQT supports an input voltage range from 4.5V to 65V, making it suitable for a wide range of automotive applications.

Q: Can TPS92512DGQT drive multiple LEDs in series? A: Yes, TPS92512DGQT can drive multiple LEDs in series by utilizing its integrated boost converter and adjustable output voltage.

Q: What is the maximum output current supported by TPS92512DGQT? A: TPS92512DGQT can support a maximum output current of up to 1.5A, allowing it to drive high-power LEDs.

Q: Does TPS92512DGQT have any built-in protection features? A: Yes, TPS92512DGQT includes various protection features such as overvoltage protection (OVP), overcurrent protection (OCP), and thermal shutdown.

Q: Can TPS92512DGQT be used in dimming applications? A: Yes, TPS92512DGQT supports both analog and PWM dimming control, providing flexibility in adjusting the brightness of the LEDs.

Q: Is TPS92512DGQT compatible with both low-side and high-side current sensing? A: Yes, TPS92512DGQT supports both low-side and high-side current sensing, allowing for different current sensing configurations.

Q: What is the operating frequency of TPS92512DGQT? A: TPS92512DGQT operates at a fixed frequency of 2.1MHz, enabling compact external components and reducing electromagnetic interference (EMI).

Q: Can TPS92512DGQT operate in a wide temperature range? A: Yes, TPS92512DGQT has a wide operating temperature range from -40°C to 125°C, making it suitable for automotive applications.

Q: Does TPS92512DGQT require any external compensation components? A: No, TPS92512DGQT features an internally compensated control loop, eliminating the need for external compensation components.

Please note that these answers are general and may vary depending on the specific application and design considerations.