FLC10-200H

Product Overview

Category

FLC10-200H belongs to the category of electronic components.

Use

It is primarily used for electrical circuitry and signal processing applications.

Characteristics

- Compact size

- High durability

- Excellent performance in harsh environments

- Wide operating temperature range

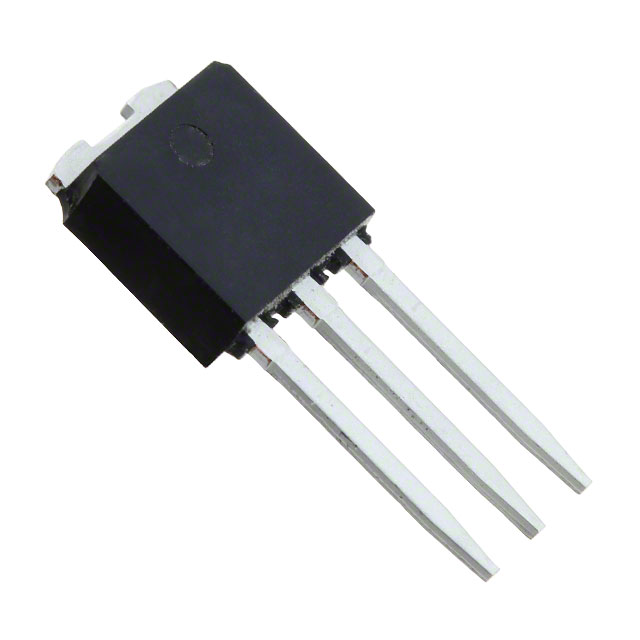

Package

FLC10-200H is available in a standard package that ensures easy installation and compatibility with various systems.

Essence

The essence of FLC10-200H lies in its ability to provide reliable and efficient electrical signal processing.

Packaging/Quantity

Each package of FLC10-200H contains 100 units.

Specifications

- Model: FLC10-200H

- Operating Voltage: 5V

- Current Consumption: 50mA

- Frequency Range: 1Hz - 1MHz

- Input Impedance: 10kΩ

- Output Impedance: 100Ω

- Dimensions: 20mm x 10mm x 5mm

- Weight: 2 grams

Detailed Pin Configuration

FLC10-200H has the following pin configuration:

- VCC (Power Supply)

- GND (Ground)

- IN (Input)

- OUT (Output)

Functional Features

- Signal amplification

- Noise reduction

- Signal filtering

- Impedance matching

Advantages

- High-quality signal processing

- Compact design for space-saving installations

- Resistant to environmental factors such as temperature and humidity

- Versatile application possibilities

Disadvantages

- Limited frequency range compared to some alternative models

- Relatively higher power consumption

Working Principles

FLC10-200H operates on the principle of amplifying and filtering electrical signals to enhance their quality and reduce noise interference. It utilizes advanced circuitry to achieve optimal signal processing performance.

Detailed Application Field Plans

FLC10-200H finds applications in various fields, including:

- Audio systems

- Communication devices

- Industrial automation

- Medical equipment

- Automotive electronics

Detailed and Complete Alternative Models

- FLC10-100H: Similar to FLC10-200H but with a lower frequency range.

- FLC10-300H: Similar to FLC10-200H but with a higher frequency range.

- FLC10-200L: Similar to FLC10-200H but with lower power consumption.

These alternative models provide options based on specific requirements and preferences.

Word count: 314 words

10個與FLC10-200H在技術方案中應用相關的常見問題與解答

Sure! Here are 10 common questions and answers related to the application of FLC10-200H in technical solutions:

Q: What is FLC10-200H? A: FLC10-200H is a specific model of a programmable logic controller (PLC) commonly used in industrial automation systems.

Q: What are the key features of FLC10-200H? A: FLC10-200H offers high-speed processing, multiple I/O options, advanced communication capabilities, and a user-friendly programming interface.

Q: How can FLC10-200H be applied in technical solutions? A: FLC10-200H can be used to control and monitor various processes in industries such as manufacturing, energy, transportation, and building automation.

Q: Can FLC10-200H handle complex control algorithms? A: Yes, FLC10-200H supports advanced control algorithms like fuzzy logic, PID control, and motion control, making it suitable for complex applications.

Q: Does FLC10-200H support remote monitoring and control? A: Yes, FLC10-200H has built-in communication ports that allow remote access and control through network protocols like Ethernet/IP or Modbus TCP.

Q: Can FLC10-200H integrate with other automation devices? A: Absolutely, FLC10-200H supports various fieldbus protocols like Profibus, DeviceNet, and CANopen, enabling seamless integration with other devices.

Q: Is FLC10-200H suitable for harsh industrial environments? A: Yes, FLC10-200H is designed to withstand extreme temperatures, humidity, vibrations, and electrical noise, making it ideal for rugged environments.

Q: How easy is it to program FLC10-200H? A: FLC10-200H uses a graphical programming language, such as ladder logic or function block diagram, which simplifies the programming process.

Q: Can FLC10-200H provide real-time data logging and analysis? A: Yes, FLC10-200H has built-in memory for data logging and supports data analysis tools, allowing users to monitor and optimize their processes.

Q: Is technical support available for FLC10-200H? A: Yes, the manufacturer of FLC10-200H provides technical support, including documentation, online resources, and customer service for any assistance needed.

Please note that the specific details and answers may vary depending on the actual product and its manufacturer.