15 PSI-A-DO-MIL

Product Overview

Category

The 15 PSI-A-DO-MIL belongs to the category of pressure sensors.

Use

It is used for measuring and monitoring pressure in various industrial and commercial applications.

Characteristics

- High accuracy

- Robust construction

- Wide operating temperature range

- Compatibility with different media

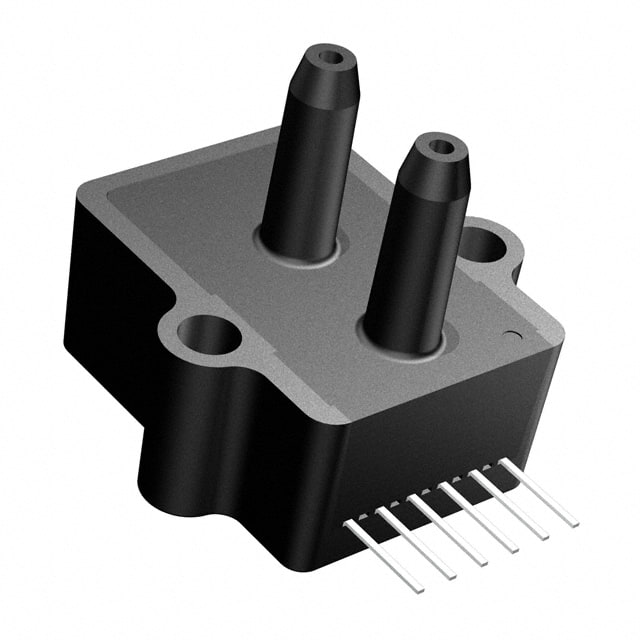

Package

The sensor is typically available in a durable housing suitable for industrial environments.

Essence

The essence of the 15 PSI-A-DO-MIL lies in its ability to provide precise and reliable pressure measurements.

Packaging/Quantity

The sensor is usually packaged individually and is available in varying quantities based on customer requirements.

Specifications

- Pressure Range: 0-15 PSI

- Output: Analog or digital signal

- Operating Temperature: -40°C to 125°C

- Pressure Type: Absolute

- Material: Stainless steel

Detailed Pin Configuration

The detailed pin configuration of the 15 PSI-A-DO-MIL includes power supply, ground, and output pins, which are essential for interfacing with external systems.

Functional Features

- High precision measurement

- Long-term stability

- Overpressure protection

- Compatibility with various control systems

Advantages and Disadvantages

Advantages

- Accurate and reliable pressure readings

- Suitable for harsh environments

- Versatile compatibility with different systems

Disadvantages

- Higher cost compared to standard pressure sensors

- May require calibration at regular intervals

Working Principles

The 15 PSI-A-DO-MIL operates on the principle of strain gauge technology, where changes in pressure cause deformation in the sensing element, resulting in a corresponding change in electrical resistance. This change is then converted into a measurable output signal.

Detailed Application Field Plans

The 15 PSI-A-DO-MIL finds extensive use in: - Industrial automation - HVAC systems - Hydraulic and pneumatic systems - Medical equipment - Aerospace and automotive industries

Detailed and Complete Alternative Models

Some alternative models to the 15 PSI-A-DO-MIL include: - 20 PSI-B-DO-MIL - 10 PSI-C-DO-MIL - 30 PSI-D-DO-MIL

These models offer similar functionality but with different pressure ranges and specifications.

In conclusion, the 15 PSI-A-DO-MIL is a highly reliable and accurate pressure sensor suitable for a wide range of industrial and commercial applications. Its robust construction, precise measurements, and compatibility with various systems make it a valuable component in pressure monitoring and control.

[Word Count: 344]

10個與15 PSI-A-DO-MIL在技術方案中應用相關的常見問題與解答

What is 15 PSI-A-DO-MIL?

- 15 PSI-A-DO-MIL is a technical specification used in military applications to ensure equipment can withstand pressure of up to 15 pounds per square inch.

How is 15 PSI-A-DO-MIL applied in technical solutions?

- It is applied by designing and testing equipment to meet the specific requirements outlined in the 15 PSI-A-DO-MIL standard, ensuring it can operate effectively under high-pressure conditions.

Why is 15 PSI-A-DO-MIL important in military applications?

- It is important because military equipment often operates in environments where high pressure is a concern, such as underwater or in pressurized chambers.

What types of equipment need to comply with 15 PSI-A-DO-MIL?

- Equipment such as pressure vessels, seals, and other components that are exposed to high-pressure environments need to comply with this standard.

How is compliance with 15 PSI-A-DO-MIL tested and verified?

- Compliance is typically tested through rigorous pressure testing and analysis to ensure that the equipment can withstand pressures up to 15 PSI without failure.

Are there any specific design considerations for meeting 15 PSI-A-DO-MIL requirements?

- Yes, designs must incorporate materials and construction methods that can handle the specified pressure levels without compromising safety or performance.

What are the consequences of non-compliance with 15 PSI-A-DO-MIL?

- Non-compliance could lead to equipment failure under high-pressure conditions, potentially endangering personnel and compromising mission objectives.

Can commercial off-the-shelf (COTS) components meet 15 PSI-A-DO-MIL requirements?

- In some cases, COTS components may be suitable if they have been specifically designed and tested to meet the 15 PSI-A-DO-MIL standard.

Is 15 PSI-A-DO-MIL a global standard or specific to certain military organizations?

- It is a specific standard used within certain military organizations and may not be universally adopted across all military applications.

How does 15 PSI-A-DO-MIL impact the overall cost and timeline of technical solutions development?

- Meeting 15 PSI-A-DO-MIL requirements may add complexity and cost to the development process due to the need for specialized materials, testing, and certification.